Idling consumes over 6 billion gallons of diesel and gasoline each year, half of which is from medium- and heavy-duty vehicles. Idling wastes money. One 2012 school bus idling for 200 hours burns up to $491 of diesel. In addition, vehicle idling increases pollutant emissions, especially if the engine is not operating at an optimal temperature, and produces 2.1 tons of greenhouse gas emissions from idling annually (AFLEET), equivalent to driving a typical passenger vehicle over 4,500 miles.

The Environmental Protection Agency (EPA) warns that "Diesel exhaust is designated 'carcinogenic to humans' by the International Agency for Research on Cancer (IARC) and it contains significant levels of particulate matter (PM). Idling exposes children to these carcinogens.” Also, according to the EPA, exhaust from one minute of idling results in more carbon monoxide exposure than smoking three packs of cigarettes. This is especially harmful to the lungs of students near idling vehicles.

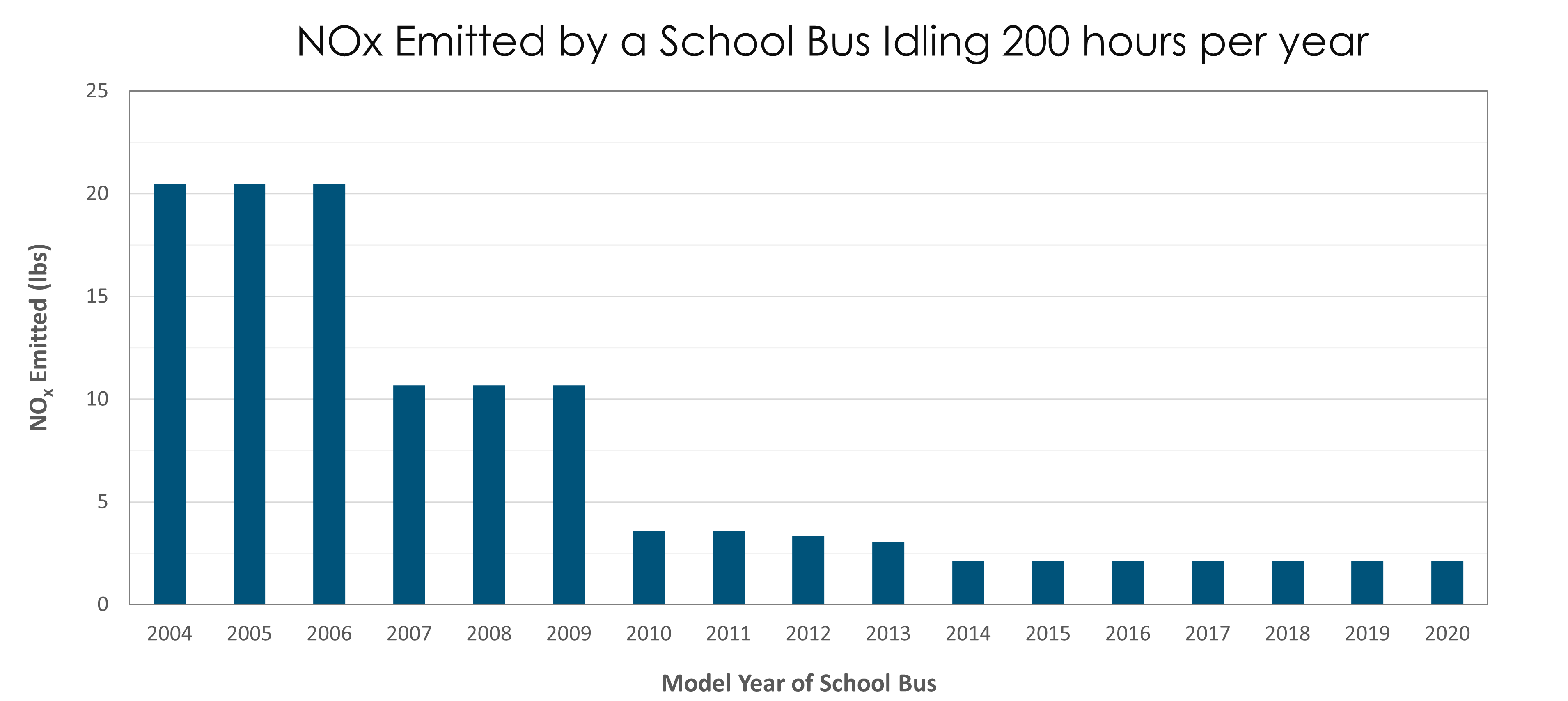

Vehicle pollutants emitted while idling increase with age. The graph below shows that older school buses, pre-2006, emit nearly 10 times as much NOx as a new school bus.

The strategies below can help reduce the emissions associated with idling, reduce costs from wasted fuel, and reduce additional wear on the engine. According to the South Carolina Department of Health and Environmental Control, “Idling is harder on the engine than restarting. Frequent restarting causes only about $10 worth of wear-and-tear per year, whereas idling leaves fuel residues that damage engine components and cause higher maintenance costs over time.”

-

Adopt a School Bus Anti-Idling Policy or Standard Operating Procedure (SOP)

|

Myth: It's better for an engine to run at low speed (idling) than to run at regular speed

|

Fact: Running an engine at low speed causes twice the wear on internal parts as driving at regular speeds. Source: EPA

|

-

Ensure operators are aware of the policy through signage and enforcement.

-

Place visible signage communicating the idle reduction policy/SOP

-

Place stickers in vehicles, on keychains, or email staff and vendors reminding them of the idling policy/SOP

-

Monitor/enforce policy/SOP compliance

-

Pull keys from operators who are not following the policy/SOP

-

Use GPS/telematics to monitor vehicle idling

-

Suspend contracts with drivers who routinely violate policy/SOP

-

Conduct yearly driver training on idling

-

Change driver behavior to reduce idling

-

Utilize technology to reduce idling

-

Install GPS/Telematics on vehicles to collect data and monitor idling

-

-

Install aftermarket devices that help prevent or reduce idling such as engine block heaters for school buses in colder climates and air heaters, coolant heaters, auxiliary power systems, and waste-heat management recovery systems for light- and medium-duty vehicles

Idle Reduction Resources

The more miles a vehicle travels, the more it contributes to air pollution. Vehicle Miles Traveled is the measure of cumulative miles traveled by all vehicles in the region — a number that grows annually due to the increasing population in North Texas. By optimizing your routes effectively, you can reduce vehicle emissions and save money on fuel use. Below are some strategies to reduce the miles traveled of school buses and white fleet vehicles.

-

Optimize routes for vehicles that drive in fixed routes. Effective route optimization can reduce the number of bus routes, maximize the number of students per bus, and reduce the distance buses travel without students.

-

Track and analyze vehicle fuel consumption and miles traveled to target individual vehicles and routes for fuel and emissions reduction

-

Use specialized software to help optimize routes

-

Go to Capterra for a list of school bus routing software

-

Install telematics or similar technology for data collection and identify areas to improve

-

Plan routes to avoid hills, traffic congestion, and low speeds

-

Reduce idling time on routes by optimizing for right-hand turns where possible

-

-

-

Look for opportunities to utilize carpooling between staff

Vehicle Miles Traveled Reduction Resources

Establishing or improving your driver training methods can help reduce fuel usage and emissions while improving skills, performance, and safety. According to the Department of Energy, drivers that rapidly accelerate and brake can lower fuel economy by 15 percent to 30 percent at highway speeds and 10 percent to 40 percent in traffic. According to the Alternative Fuel Life-Cycle Environmental and Economic Transportation (AFLEET) Tool, this can increase annual fuel costs by up to $1,120. The strategies below can help improve driver training and reduce emissions associated with driving techniques

-

Provide new-hire training as employees come on board, as well as annually. During the training be sure to cover the following:

-

Share any relevant training resources with fellow fleets and/or with NCTCOG

-

Implement ‘eco-driving’ methods for your bus fleet and white fleet:

-

Avoid unnecessary idling – Idling can increase emissions; turn off the engine if stopped for more than a minute, except while in traffic (see idle reduction tab above)

-

Eliminate the use of drive-thrus – Walk inside to reduce idling

-

Avoid aggressive driving – Speeding and aggressive accelerating and braking greatly decreases vehicle efficiency

-

Drive defensively – More conservative driving

-

Reduce air conditioner and heater use – Vehicle air conditioner/heater usage is one of the biggest users of energy

-

For white fleet vehicles, open windows instead of using the air conditioner when traveling below highway speeds

-

Choose ‘economy’ setting or ‘recirculation’ setting to increase efficiency of air conditioner

-

Reduce vehicle load – Increased weight from unneeded equipment decreases vehicle efficiency

-

Use economy mode – Some vehicles have this setting to increase fuel efficiency

Driver Training Resources

Rightsizing

Rightsizing is using the most fuel efficient, lowest emitting vehicle for an operation. Often rightsizing results in the use of a smaller vehicle for a particular operation. A 10 percent reduction in vehicle weight can improve fuel economy by 6 to 8 percent, saving $4,000 over the lifetime of a school bus. Rightsizing can also result in lower emissions and less noise. Examples of rightsizing are:

-

Using a small sedan for administrative duties rather than an SUV or pickup truck

-

Using a smaller bus or van for a Special Education route with fewer students rather than a full-size bus

-

Replacing a V8 truck with a 6- or 4-cylinder truck or SUV where hauling or towing cargo capabilities are not needed

To identify fleet operations using oversized, less-efficient vehicles unnecessarily, consider the following data points for the white and yellow fleets:

-

White Fleet - Vehicle purpose, towing need, frequency of use, cargo space needs, number of passengers

-

Yellow Fleet – Number of students riding

Downsizing

Downsizing is eliminating excess, under-utilized vehicles and equipment from the fleet, which can result in maintenance savings, fuel savings, and fewer emissions. To retire vehicles in a consistent manner, consider creating a formal replacement/attrition schedule. Examples of downsizing are:

- Using a motor pool made up of low-emitting vehicles. These could be vehicles used occasionally for traveling to administrative meetings, etc. Employees should be encouraged to use the motor pool for work trips rather than their personal vehicle.

-

Removing older vehicles no longer assigned to a specific job/role (ghost fleet)

-

Not replacing vehicles and equipment as they age out of the fleet, if possible

To identify under-utilized and unnecessary vehicles, consider the following data points for the white and yellow fleets:

-

White Fleet - Daily and annual miles to identify underutilization; if underutilized, consider removal or use in motorpool

-

Yellow Fleet - Use route optimization to look for opportunities to remove buses

Fleet Utilization Study

To achieve rightsizing and downsizing, fleets can consider conducting a fleet utilization study. To conduct a fleet utilization study

-

Develop Utilization Criteria

-

Metrics used for evaluating utilization: odometer, days used, fuel consumption, number of trips, outside rentals required, reimbursements due to personal vehicle usage, age of vehicles

-

Establish a vehicle utilization review board

-

At Least Every 5 Years, Conduct a Fleet Utilization Study to Identify Opportunities to:

-

Remove underutilized assets

-

Lease vehicles

-

Share assets - use a motorpool

-

Adjust personnel ratios

-

Rotate vehicle assignments

-

Identify Critical Vehicles

-

Determine the Optimal Fleet Profile

-

Acquire New, Rightsized Vehicles or Dispose of Unnecessary Vehicles

Resources on Rightsizing and Downsizing:

Other strategies to improve fleet efficiency and reduce costs are included below.

-

Keep vehicles and equipment properly maintained and tires properly inflated

-

-

Use the recommended motor oil grade and one that contains friction-reducing additives (look for “Energy Conserving” on the American Petroleum Institute Service Symbol)

-

Address check engine indicators promptly

-

Park in shaded areas or install shaded parking to minimize evaporative emissions/fuel losses

-

Install low rolling resistance tires

-

Support peer fleets’ efforts to implement fuel or emission reducing activities by sharing and maximizing resources

-

Partner with other organizations through mutually beneficial agreements to facilitate sharing of refueling stations, equipment, maintenance facilities, and training materials

-

Arrange to share maintenance facilities which are retrofitted to accommodate alternative fuels

-

Engage fellow fleets in cooperative purchasing efforts

-

Maximize use of vehicles and equipment with the lowest emissions. For example, place new buses on the longest routes and move the oldest, highest-emitting vehicles to backup service roles.